Laser Alignment Services for Reliable Soft Foot Alignment Solutions in Kolkata Industries

- Lasertech Solution

- Jan 10

- 3 min read

In industrial environments, reliable equipment performance depends on correct installation and daily maintenance. One commonly faced problem is soft foot condition that disturbed machine alignment and cause vibration or wear. Fixing soft foot alignment is important to achieve smoother operation, improved accuracy, reduced downtime, and extended machinery life through proper checks and corrections.

Understanding Soft Foot Alignment

A soft foot condition happens when one or more machine feet do not sit identically on the base or foundation. You know, the mounting bolts are secure, machine frame bends or twists, creating inside stress that assume shaft alignment, increases vibration, and speeds up wear.

Soft foot problems are usual in rotating machinery like pumps, motors, compressors, and fans. Even a very small gap under a foot is creating serious performance and reliability issues if it is not corrected in time.

Why Fixing Soft Foot Alignment Is Important?

Fixing soft foot alignment is important because it directly affects the accuracy of machine alignment. When soft foot exists, the machine is shift after secure the bolts, create the alignment to change and resulting in misalignment during normal operation and reduced equipment reliability.

Uncorrected soft foot can cause:

Increased vibration levels

Loose mounting bolts

Premature bearing and seal wear

Higher energy consumption

Reduced overall machinery performance

From an industrial maintenance view, correcting soft foot is a low cost solution that less downtime and significantly increase machinery life.

The Relationship Between Soft Foot and Vibration

One of the main purposes of proper alignment is to reduce vibration, but soft foot works against this by creating uneven stress in the machine frame. This stress transfers to bearings, shafts, and couplings, causing higher vibration levels even when alignment looks correct. Just as a focuses on building a stable digital foundation, correcting soft foot is essential for maintaining a stable and reliable machine foundation.

Over time, constant vibration leads to fatigue, cracking, and bearing failure prevention. Correcting soft foot is therefore a basic and important step in any successful vibration cutting and bearing failure prevention strategy.

Detecting a Soft Foot Condition

Accurate detection is the first step toward correction, using show and good inspection methods.

Feeler gauges help check gaps under loosened machine feet.

Space dial indicators step foot movement as bolts tightened.

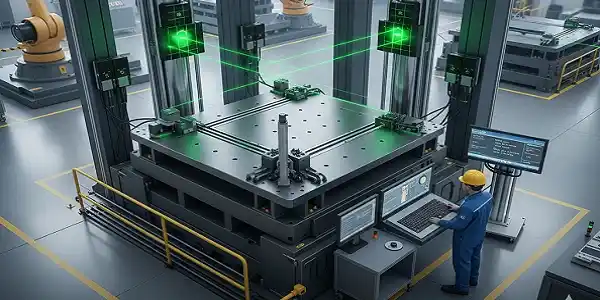

Laser alignment systems correctly detect vertical movement and machine twist with a very high level of precision.

Modern laser alignment systems are mostly effective because they detect vertical movement and frame distortion with high precision. With support from Laser alignment services, these systems provide real-time data and allow technicians to correctly measure the severity of soft foot conditions, ensuring accurate correction and smoother machine performance.

Methods for Fixing Soft Foot Alignment

Once finding, several corrective actions to be taken:

Precision Shimming

Precision shimming is the most common corrective action. And, how high quality shims are placing under machine feet to make sure full and even contact with the base fixing soft foot alignment.

Correcting Bent or Damaged Feet

Bent or damaged feet must be machining or ground to restore proper flatness and stability.

Base and Foundation Repairs

Base or foundation issues such as warped may needs machining or re-grouting to stop recurring soft foot.

Eliminating External Forces

External forces like piping strain must be removed to avoid inducing soft foot after alignment.

Rechecking soft foot is important ago performing final shaft alignment to make sure long term accuracy.

Benefits of Proper Soft Foot Correction

Correcting soft foot provides important reliability, performance, and maintenance benefits.

Improved machinery performance

Lower vibration levels

More accurate machine alignment

Extended bearing and coupling life

Better bearing failure prevention

Reduced maintenance costs

Like reliability focused maintenance teams, soft foot correction delivers high impact improvements with clear, limited performance results.

Best Practices for Industrial Maintenance

To stop recurring issues:

Always check like soft foot before alignment

Use proper tools and calibrated laser alignment service

Train technicians on soft foot detection and correction

Document alignment and correction procedures

Involve soft foot inspections in daily maintenance routines helps maintain consistent and good industrial tools operation.

Conclusion

Fixing soft foot alignment is an important yet often missed step in ensuring smooth, efficient, and reliable machine operation. By detecting and correcting soft foot conditions, maintenance teams can reduce vibration, protect bearings, and improve overall machinery performance. With the support of shaft alignment services in Delhi, addressing soft foot becomes a critical part of any alignment process and is essential for long-term operational success.

Comments