Eliminate Vibration and Downtime with Shaft Alignment in Delhi

- Lasertech Solution

- Oct 29, 2025

- 2 min read

In industrial operations, machine reliability drives productivity and safety. One frequently overlooked cause of failures is shaft misalignment. Even tiny errors can lead to excessive vibration, premature bearing and seal failures, and wasted energy.

Professional shaft alignment services in Delhi precisely align rotating components such as motors, pumps, compressors, turbines, and gearboxes. Accurate alignment extends equipment life, reduces maintenance, and improves overall operational efficiency.

What Is Shaft Alignment?

Shaft alignment ensures two or more rotating shafts share the same centerline. In practical terms, it confirms that connected machines (for example, a motor and a pump) and EOT Crane are aligned both horizontally and vertically.

Why it matters:

Even sub‑millimeter misalignments can escalate vibration and heat

Energy consumption rises as components fight friction and load

Bearings, seals, and couplings wear faster, increasing unplanned downtime

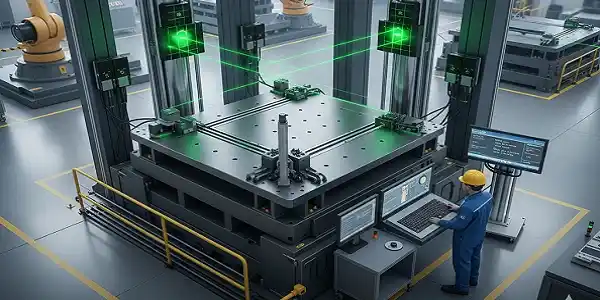

Modern teams use laser shaft alignment tools to achieve fast, repeatable, highly accurate results and to remove guesswork from the process.

Why Alignment Matters for Industrial Equipment

Common risks caused by misalignment:

Increased vibration that damages bearings, seals, and couplings

Added mechanical stress leading to frequent breakdowns

Higher motor load and electricity costs

Accelerated wear that shortens the service life of critical assets

Investing in professional shaft alignment services in Delhi helps prevent these issues and stabilizes production.

Benefits of Professional Shaft Alignment (Delhi NCR)

Longer equipment life: Correct alignment reduces mechanical failures and keeps machines running smoothly

Lower maintenance costs: Less wear means fewer repairs and replacements

Energy savings: Reduced friction lowers power consumption and operating costs

Protection of critical parts: Bearings, seals, and couplings last longer

Cross‑industry impact: Manufacturing, pharma, food processing, utilities, and data centers all benefit from precision alignment

Laser Shaft Alignment: The Modern Standard

Traditional dial‑indicator methods can work, but they are slower and more operator‑dependent. Laser shaft alignment delivers faster, more precise outcomes with clear documentation.

Key advantages of laser alignment:

High precision: Detects angular, parallel, and axial misalignments with tight tolerances

Speed: Shortens alignment time and reduces costly downtime

Digital reporting: Stores measurement data for maintenance logs and audits

Efficiency: Less friction and vibration translates to energy and cost savings

Compliance support: Documentation helps maintain alignment practices aligned with ISO‑based maintenance programs ISO

Why Choose a Professional Team in Delhi

With Delhi’s rapidly growing industrial base, accuracy and reliability are essential. A qualified alignment partner provides:

Advanced laser tools for complex machinery and bases

Trained technicians who interpret results correctly and make precise corrections

On‑site service to minimize disruption and restore equipment quickly

Final Words

Excessive machine vibration is expensive—and preventable. With professional shaft alignment services in Delhi, you can keep equipment at peak efficiency, cut maintenance costs, and protect your investments. Our laser alignment services ensure precise shaft positioning, reducing wear, energy loss, and unplanned downtime while maximizing machinery performance.

Don’t wait for a breakdown. Schedule an alignment to enable smoother, safer, and more efficient operations.

Comments